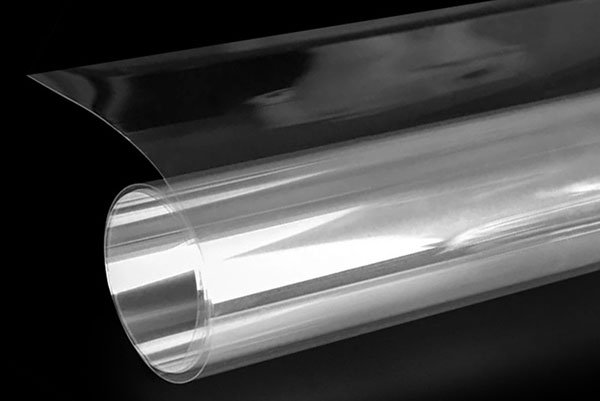

Precision electronics and medical sensors require more than just static protection—they require a clean environment. Our thermoforming ESD PET sheets are low-outgassing and halogen-free, making them safe for ISO-certified cleanrooms. The material offers glass-like transparency, allowing for easy visual inspection of parts without breaking the ESD seal. It responds beautifully to vacuum pressure, capturing sharp details and maintaining uniform wall thickness in complex molds. Whether you are producing clamshells for medical sensors or protective inserts for high-end optics, this material provides the rigid protection and electrical stability your project demands.

| Antistatic ESD PET Film | UNIT | Antistatic Silicon Free | ESD | Conductive |

| Thickness of Film Tested | mm | 0.25~1.8 | 0.25~1.8 | 0.25~1.8 |

| Width | mm | 600~ 1400 | 600~ 1400 | 600~ 1400 |

| Diameter | mm | 300~ 800 | 300~ 800 | 300~ 800 |

| Density | g/cm³ | 1.35 | 1.35 | 1.35 |

| Haze | % | 2.0(0.3mm) | 2.0(0.3mm) | 2.0(0.3mm) |

| Crystal Temperature | (℃) | 125 | 125 | 125 |

| Meliting Temperature | 248 | 248 | 248 | 248 |

| Recrystal Temperature | (℃) | 181 | 181 | 181 |

Our Advantages

Professional manufacturer and supplier of Antistatic ESD PET Sheets, offering wholesale online services with competitive pricing.

Full support for OEM & ODM projects to meet customized requirements.

Factory-direct supply ensures cost-effective and stable sourcing.

Over 10 years of export experience serving global markets.

Certified with RoHS, SGS, and ISO standards to guarantee quality and compliance.

Multiple patented technologies reflect strong innovation and product development capabilities.

In the manufacturing of semiconductor trays and electronic component carriers, the transition from a flat sheet to a three-dimensional pocket is where most ESD materials fail. Standard anti-static coatings often fracture or thin out when stretched, leaving "insulative hotspots" that can lead to catastrophic discharge events. Thermoforming ESD PET Sheeting is specifically engineered to solve this through a networked dissipative structure that maintains electrical integrity during the vacuum forming process.

The primary challenge in deep-draw thermoforming is maintaining a consistent surface resistivity ($10^6$ to $10^9$ $\Omega/sq$) across the entire part. As the PET sheet is heated and pulled into a mold, the surface area increases significantly. Our ESD PET utilizes a specialized conductive polymer matrix that "flows" with the base PET resin. Unlike topical coatings that crack like a dry lakebed under tension, our dissipative layer expands uniformly. This ensures that the bottom corners of a deep tray—the areas most prone to thinning—remain as static-safe as the flat flange.

For the production manager, the "processing window" is the difference between a high-yield run and a bin full of scrap. Our thermoforming grade PET is optimized for consistent heat absorption. It responds predictably to infrared heater banks, reaching its glass transition temperature ($T_g$) without the sagging or "webbing" common in lower-quality resins. This thermal stability allows for faster cycle times and cleaner releases from the mold, which is particularly critical when forming high-density trays for small-form-factor ICs where pocket definition must be razor-sharp.

Beyond static protection, electronics and medical packaging require chemical purity. Many ESD-safe plastics rely on carbon black or migrating fatty-acid esters, which can leave conductive slough or "greasy" residues on the components. Our ESD PET is halogen-free and low-outgassing, making it compatible with ISO Class 5 cleanrooms. It does not "bloom" or release volatile compounds over time, ensuring that the sensitive gold leads or optical sensors packaged within remain free from molecular contamination.

The final test of a thermoformed ESD tray is how it performs on an automated pick-and-place line. If the material is too brittle, the pockets will crack; if it has high surface friction, the trays will stick together (static lock). Our material is formulated for high impact strength and superior denesting. The finished trays can be stacked and de-stacked by high-speed robotics without jamming, ensuring that your automated assembly lines maintain maximum Units-Per-Hour (UPH).

Stretch-Stable Surface Resistivity ($10^6 – 10^9 \Omega$):Unlike standard anti-static sheets that lose their properties when stretched, our thermoforming grade features a conductive polymer matrix that "flows" with the plastic. This ensures that even in deep-draw pockets, the material maintains its dissipative path, eliminating "insulative hotspots" that can lead to static discharge.

Wide Processing Window (Uniform Heat Absorption):Engineered for predictable behavior under infrared heater banks, this PET sheet reaches its forming temperature without the premature "sagging" or webbing seen in lower-quality resins. This results in faster cycle times and a significantly lower scrap rate during high-volume production runs.

Low-Outgassing & Cleanroom Compatible:Formulated specifically for the semiconductor and medical industries, our ESD PET is halogen-free and does not rely on migrating surfactants (fatty acids). This prevents "blooming" and molecular contamination, making it safe for ISO Class 5 cleanroom environments.

Superior Denesting & Low Surface Friction: One of the biggest headaches in automated assembly is "tray stick." Our material is treated with internal slip agents that work in tandem with the ESD layer to allow for smooth, high-speed de-stacking by pick-and-place robotics, directly increasing your Units-Per-Hour (UPH).

High Pocket Definition & Impact Strength: The material's high melt strength allows for the formation of razor-sharp details and complex geometries. Even after forming, the trays remain rigid and impact-resistant, providing a secure "clamshell" fit that protects sensitive components from mechanical shock during international shipping.

Recyclable & Environmentally Compliant: Maintaining your ESG (Environmental, Social, and Governance) targets is easy with our 100% recyclable APET-based structure. It is compliant with RoHS and REACH standards, ensuring your packaging is as safe for the planet as it is for your sensitive electronic hardware.