Let’s be honest—matte surfaces are usually a nightmare to keep clean. One touch and you’re left with oily marks that won't budge. We’ve changed the game with our next-gen Soft-Touch PETG film. Engineered with an advanced anti-smudge topcoat, this film repels fingerprints and resists the micro-scratches that ruin cheaper alternatives. It’s food-safe, non-toxic, and tough enough to handle the daily grind of a family kitchen while maintaining that "straight-from-the-showroom" velvet texture.

Our Advantages

Professional manufacturer and supplier of soft touch PETG film , offering wholesale online services with competitive pricing.

Full support for OEM & ODM projects to meet customized requirements.

Factory-direct supply ensures cost-effective and stable sourcing.

Over 10 years of export experience serving global markets.

Certified with RoHS, SGS, and ISO standards to guarantee quality and compliance.

Multiple patented technologies reflect strong innovation and product development capabilities.

| Product name | PET Sheet, PETG Sheet,Polyethylene Terephthalate Sheet, PET Rollstock, Polyester Sheet, Rigid PET Film. |

| Product Category | APET, PETG, GAG, RPET, PET/EVOH/PE, PET/EVOH/PET, PET/PE, etc. |

| Shape | Roll/Sheet |

| Thickness | 0.18~1mm or Customized |

| Width | 300~1400mm |

| Quality | Virgin/Recycled |

| PET Roll Diameter | ≤38 inch |

| Die Cutting Size | A2, A3, A4 or customized according to requirements. |

| Packing | PE film inside + kraft outside+pallet (paper tube diameter: 76mm, thickness: 10mm) |

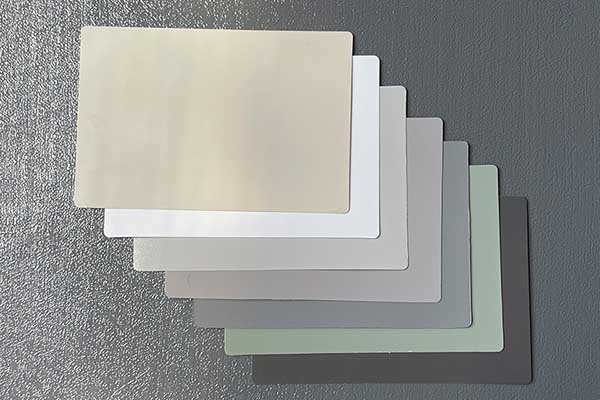

| Color | Clear, White, Blue, Brown, Pink, Green, Yellow or Customized. |

| Performance | Anti-fog, ESD (Anti-static, Conductive, Static dissipative), Corona, Printing, Coating, High impact, EVOH high barrier, Waterproof, Oil-proof, Anti-UV, etc. |

| Processing technology | Thermoforming Vacuum Blister Forming, Die Cutting. |

| Hardness | Rigid/Semi-rigid |

For a long time, the furniture industry faced a frustrating trade-off. You could have a beautiful matte finish, but you had to accept that it would be a "fingerprint magnet." Or, you could choose a durable gloss, but lose that sophisticated, muted aesthetic. Our Soft-Touch PETG Film was engineered specifically to break that cycle. It represents a shift toward "sensory design," where the way a cabinet feels is just as vital as how it looks in a catalog.

The secret behind the success of this velvet-finish PETG foil lies in its surface energy. Traditional laminates often feel cold, hard, and undeniably synthetic. By contrast, our soft-touch technology creates a micro-textured surface that mimics the warmth of natural organic materials. It creates a "soft-focus" effect on furniture, absorbing ambient light to eliminate harsh glares. This makes it the premier soft-touch furniture overlay for modern, minimalist spaces where "quiet luxury" is the goal.

We built this film for real homes—places where coffee spills happen, kids leave sticky handprints, and life is lived. Our smudge-proof matte cabinet film features an advanced oleophobic layer. Instead of absorbing skin oils, the surface repels them, allowing the finish to remain deep and consistent throughout the day.

But it isn't just about cleanliness; it’s about longevity. Many matte surfaces are prone to "burnishing"—those shiny marks left behind by a stray fingernail or a sliding plate. Our high-durability PETG laminate is reinforced to resist these micro-scratches, ensuring that the elegant, zero-gloss decorative wrap stays looking brand new, even in high-traffic areas like kitchen islands and office desks.

Beyond the aesthetics, there is a technical peace of mind that comes with PETG. Unlike PVC, which can release chlorine gas and harmful VOCs, our PETG film is fundamentally food-safe and recyclable. It is a non-toxic solution that doesn't sacrifice performance for sustainability. For manufacturers and designers, this means providing a product that isn't just beautiful to look at and touch, but one that contributes to a healthier indoor environment.

In an industry where "standard" is no longer enough, our Soft-Touch PETG series offers a path to distinction. It’s a material that proves you really can have it all: the velvet feel, the matte look, and the rugged durability required for modern life.

The defining characteristic of Skin-Sense film is its unique surface texture. Unlike traditional high-gloss or standard matte finishes that can feel like hard plastic, this film uses a specialized soft-touch coating. It provides a warm, velvet-like sensation under the fingertips—often described as "baby-skin" soft—which adds a layer of emotional comfort and "quiet luxury" to home furniture.

One of the biggest headaches with matte surfaces is their tendency to show every oily fingerprint and smudge. Skin-Sense PETG is engineered with a high-density, non-porous surface that repels oils. This "self-cleaning" property means that even in high-traffic areas like kitchen cabinets or wardrobe doors, the film maintains a clean, unblemished appearance without the need for constant wiping.

While it feels soft, the material is surprisingly tough. The outer layer is treated with a hardening process (often inspired by mobile phone screen protection technology). This gives it a high level of resistance against daily wear and tear, preventing the micro-scratches that usually dull the appearance of furniture over time. It offers the "painted look" of high-end lacquer but with much higher impact and scratch resistance.

PETG is a non-crystalline copolyester that is fundamentally safer than traditional PVC. It is BPA-free and often meets FDA food-contact standards. Because it is composed only of Carbon, Hydrogen, and Oxygen, it does not release toxic chlorine gas or harmful VOCs (Volatile Organic Compounds) into your home. It’s an ideal choice for health-conscious families and sustainable building projects.

Traditional finishes often fade or turn yellow when exposed to indoor lighting or indirect sunlight. Skin-Sense PETG films utilize high-quality imported masterbatches and UV-stabilizers. This ensures that the deep, elegant colors (like Morandi grays or creamy whites) remain vibrant and consistent across different production batches, maintaining the aesthetic integrity of the interior for years.

For manufacturers, the benefit lies in the material's flexibility. PETG has a lower shrinkage rate and better toughness than standard PET. It can be easily applied using flat lamination or vacuum forming without cracking at the edges. Its ability to wrap around complex curves and "memory" properties during the pressing process result in a seamless, professional finish that mimics expensive custom-painted millwork.