The biggest challenge with matte surfaces has always been "burnishing"—those ugly shiny marks left behind by daily wear. Our Skin-Sense Matte PETG film is specifically engineered to resist micro-abrasions while maintaining its signature soft-touch feel. Unlike PVC, our PETG base is incredibly stable under heat, making it perfect for flat lamination or vacuum pressing. It’s a smudge-proof, scratch-resistant solution that reduces factory scrap rates and delivers a final product your clients will never want to stop touching.

Our Advantages

Professional manufacturer and supplier of skin sense matte PETG film , offering wholesale online services with competitive pricing.

Full support for OEM & ODM projects to meet customized requirements.

Factory-direct supply ensures cost-effective and stable sourcing.

Over 10 years of export experience serving global markets.

Certified with RoHS, SGS, and ISO standards to guarantee quality and compliance.

Multiple patented technologies reflect strong innovation and product development capabilities.

| Product name | PET Sheet, PETG Sheet,Polyethylene Terephthalate Sheet, PET Rollstock, Polyester Sheet, Rigid PET Film. |

| Product Category | APET, PETG, GAG, RPET, PET/EVOH/PE, PET/EVOH/PET, PET/PE, etc. |

| Shape | Roll/Sheet |

| Thickness | 0.18~1mm or Customized |

| Width | 300~1400mm |

| Quality | Virgin/Recycled |

| PET Roll Diameter | ≤38 inch |

| Die Cutting Size | A2, A3, A4 or customized according to requirements. |

| Packing | PE film inside + kraft outside+pallet (paper tube diameter: 76mm, thickness: 10mm) |

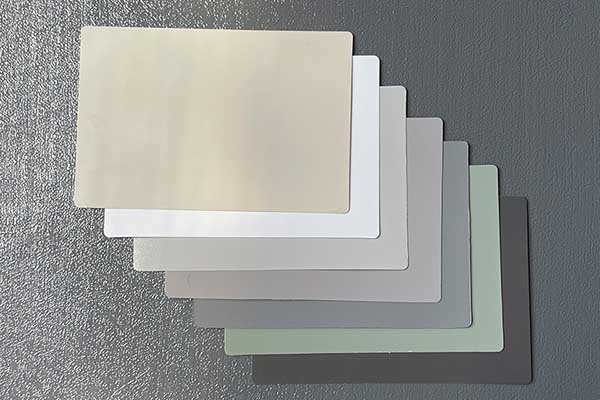

| Color | Clear, White, Blue, Brown, Pink, Green, Yellow or Customized. |

| Performance | Anti-fog, ESD (Anti-static, Conductive, Static dissipative), Corona, Printing, Coating, High impact, EVOH high barrier, Waterproof, Oil-proof, Anti-UV, etc. |

| Processing technology | Thermoforming Vacuum Blister Forming, Die Cutting. |

| Hardness | Rigid/Semi-rigid |

In the world of high-end millwork, the "perfect matte" has long been the industry’s "Holy Grail." Designers have always craved the muted, sophisticated look of a hand-painted finish, but the reality was often a surface that scratched at the slightest touch and absorbed fingerprints like a sponge. The introduction of Skin-Sense Matte PETG Film has fundamentally changed that equation, offering a surface that is as resilient as it is beautiful.

The standout feature of this zero-gloss PETG matte film is its ability to manipulate light. While standard surfaces reflect light in a single direction—creating glares and hot spots—our skin-sense technology utilizes a micro-structured topcoat that scatters light across the surface. This creates a soft-touch anti-glare foil effect that gives cabinetry a deep, shadow-rich appearance. The result is a "soft-focus" aesthetic that makes colors look more saturated and surfaces look more expensive.

The "Skin-Sense" name isn't just marketing; it refers to the material's unique tactile energy. By mimicking the warm, velvet-like texture of natural organic materials, this skin-feel matte furniture wrap removes the clinical, cold sensation of traditional plastic laminates. However, this softness doesn't mean fragility.

We have integrated an advanced oleophobic (oil-repelling) layer into the film’s structure. This ensures that even in high-traffic areas, the high-performance PETG overlay remains free of unsightly smudge marks and grease streaks. For homeowners, this means the end of constant buffing and cleaning. For manufacturers, it means providing a product that maintains its showroom-quality finish long after the installation is complete.

Beyond its sensory appeal, this non-reflective soft-touch laminate serves as a rugged shield for the underlying substrate. PETG is inherently more stable than PVC, offering superior resistance to yellowing from UV exposure and better structural integrity during the thermoforming process. It resists "burnishing"—the shiny rub marks that typically ruin matte surfaces over time—allowing the furniture to withstand the micro-abrasions of daily use without losing its velvet-matte integrity.

As we move toward a future of "Quiet Luxury," the materials we choose must speak to both the eyes and the hands. Skin-Sense PETG is the bridge between those two worlds, providing a sustainable, non-toxic, and undeniably premium finish for the modern home.

The defining characteristic of Skin-Sense film is its unique surface texture. Unlike traditional high-gloss or standard matte finishes that can feel like hard plastic, this film uses a specialized soft-touch coating. It provides a warm, velvet-like sensation under the fingertips—often described as "baby-skin" soft—which adds a layer of emotional comfort and "quiet luxury" to home furniture.

One of the biggest headaches with matte surfaces is their tendency to show every oily fingerprint and smudge. Skin-Sense PETG is engineered with a high-density, non-porous surface that repels oils. This "self-cleaning" property means that even in high-traffic areas like kitchen cabinets or wardrobe doors, the film maintains a clean, unblemished appearance without the need for constant wiping.

While it feels soft, the material is surprisingly tough. The outer layer is treated with a hardening process (often inspired by mobile phone screen protection technology). This gives it a high level of resistance against daily wear and tear, preventing the micro-scratches that usually dull the appearance of furniture over time. It offers the "painted look" of high-end lacquer but with much higher impact and scratch resistance.

PETG is a non-crystalline copolyester that is fundamentally safer than traditional PVC. It is BPA-free and often meets FDA food-contact standards. Because it is composed only of Carbon, Hydrogen, and Oxygen, it does not release toxic chlorine gas or harmful VOCs (Volatile Organic Compounds) into your home. It’s an ideal choice for health-conscious families and sustainable building projects.

Traditional finishes often fade or turn yellow when exposed to indoor lighting or indirect sunlight. Skin-Sense PETG films utilize high-quality imported masterbatches and UV-stabilizers. This ensures that the deep, elegant colors (like Morandi grays or creamy whites) remain vibrant and consistent across different production batches, maintaining the aesthetic integrity of the interior for years.

For manufacturers, the benefit lies in the material's flexibility. PETG has a lower shrinkage rate and better toughness than standard PET. It can be easily applied using flat lamination or vacuum forming without cracking at the edges. Its ability to wrap around complex curves and "memory" properties during the pressing process result in a seamless, professional finish that mimics expensive custom-painted millwork.