Push thermoforming limits. This PET GAG film combines deep-draw capability with resistance to stress whitening, enabling sharp corners and complex geometries. With superior ESCR (environmental stress crack resistance), it’s ideal for permanent displays, machine guards, and architectural models.

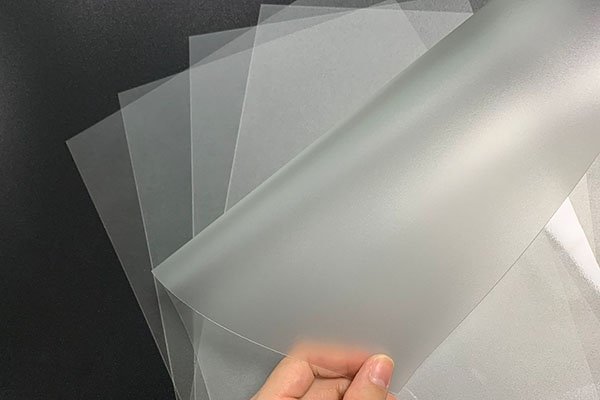

GAG plastic sheets are known for their exceptional transparency, with light transmission rates exceeding 90%, providing a high-quality aesthetic appearance. These sheets also boast a superior texture, making them ideal for various applications requiring both visual clarity and durability.

With outstanding impact resistance and rigidity, GAG plastic sheets are hard, durable, and designed to withstand high-impact conditions, making them a preferred choice for demanding environments.

The processability of GAG plastic sheets is excellent, offering a wide range of fabrication options. These sheets can be easily sawed, die-cut, drilled, laser-cut, and shaped through cold or hot bending. Additionally, they are suitable for gluing, welding, polishing, printing, and painting, offering versatility in production.

GAG plastic sheets also exhibit excellent thermoformability. They can be formed without the need for preheating, with a low shrinkage rate of approximately 0.5%. This ensures high precision, uniform thickness, and crack-free formation, providing consistent results in manufacturing processes.

Additionally, GAG plastic is eco-friendly and recyclable, making it a sustainable choice that minimizes environmental impact.

Compliant with food safety regulations, GAG plastic sheets are ideal for applications in food trays, packaging boxes, and other food-related products, ensuring both safety and performance in sensitive environments.

| PET GAG Film | UNIT | Antistatic Silicon Free | ESD | Conductive |

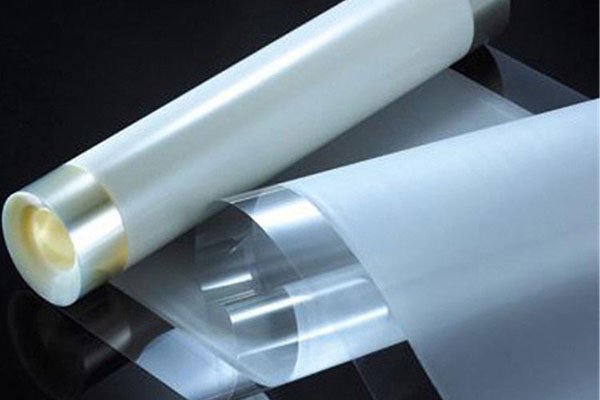

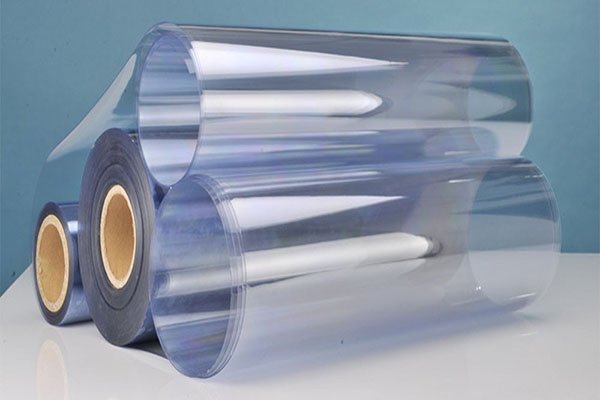

| Thickness of Film Tested | mm | 0.25~1.8 | 0.25~1.8 | 0.25~1.8 |

| Width | mm | 600~ 1400 | 600~ 1400 | 600~ 1400 |

| Diameter | mm | 300~ 800 | 300~ 800 | 300~ 800 |

| Density | g/cm³ | 1.35 | 1.35 | 1.35 |

| Haze | % | 2.0(0.3mm) | 2.0(0.3mm) | 2.0(0.3mm) |

| Crystal Temperature | (℃) | 125 | 125 | 125 |

| Meliting Temperature | 248 | 248 | 248 | 248 |

| Recrystal Temperature | (℃) | 181 | 181 | 181 |

Our Advantages

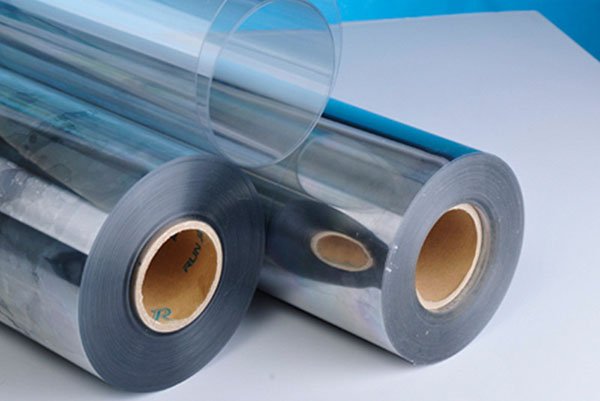

Professional manufacturer and supplier of PET GAG Roll, offering wholesale online services with competitive pricing.

Full support for OEM & ODM projects to meet customized requirements.

Factory-direct supply ensures cost-effective and stable sourcing.

Over 10 years of export experience serving global markets.

Certified with RoHS, SGS, and ISO standards to guarantee quality and compliance.

Multiple patented technologies reflect strong innovation and product development capabilities.

| Product Name | APET Sheet, PETG Sheet, RPET Sheet, GAG Sheet |

| Material | PP vacuum forming material , 100% raw material |

| Color | Transparent,black,green or any customized color |

| Thickness Tolerance | According to GB (higher than GB) |

| Application | Vacuum forming packaging, Printing, Bending, Folding box, Cards,etc. |

| Width | 300~1400mm or Customized |

| Thickness | 0.15~3mm or Customized |

| Special Treatment | Metalized, Anti-UV, Waterproof, Antistatic, Anti-fog, Frosted, Cold resistance, Heat resistance, Double-sided Matte, Conductive. |

| Features | 1.High temperature resistance, not easily melted 2.Easy to peel off and no residue requirement 3.Printable, good inking effect 4.Widely used in food and drug industry 5.Uniform thickness, smooth surface/beautiful sand ripples 6.No grains, contamination control and good processing performance |

| Sample Time | 1-3 days |

| Delivery Methods | Ocean shipping ,air transportation, express,land transportation |

| Payment Term | Credit card ,T/T,L/C,Western Union,Paypal |

| Mass Production Lead Time | 3-15 days depend on order quantity |

| Certificate | ROHS,MSDS,TDS,SGS,ISO9001 |

| Core Diameter | 3 inch or 6 inch depend on customer requirement |

| Packing | Packing in rolls and plastic pallet,pp woven with PE film and strape on pallet for each roll |

Feature 1: Permanent Co-extruded Antifog Layer

Benefit: Provides consistent, long-lasting fog resistance that does not wash off, ensuring a crystal-clear view of your product for the entire shelf life. This enhances product visibility and consumer appeal, directly reducing returns and increasing sales.

Feature 2: Superior Optical Clarity & High Gloss

Benefit: Creates a brilliant, high-quality presentation that makes fresh food, baked goods, and other products look more appealing and vibrant. This superior visual presentation helps your brand stand out in a competitive retail environment, driving purchase decisions.

Feature 3: Excellent Gas & Moisture Barrier Properties

Benefit: Extends the shelf life of fresh and sensitive products by protecting them from oxygen and moisture. This significantly reduces food spoilage and waste, improving your supply chain efficiency and profitability.

Benefit: Meets stringent regulatory standards for direct food contact, making it a safe and reliable choice for packaging meat, poultry, produce, and ready-to-eat meals. This ensures your brand compliance and builds consumer trust.

Feature 5: High Durability and Puncture Resistance

Benefit: Withstands the rigors of transportation, handling, and stacking without tearing. This ensures product integrity from your production line to the store shelf, minimizing damage-related losses and protecting your brand reputation.

Feature 6: Excellent Thermoformability & Machinability

Benefit: Runs efficiently on high-speed packaging and converting equipment, allowing for seamless integration into your existing production lines. This increases output, reduces downtime, and improves overall manufacturing efficiency.