In medical and laboratory settings, frequent disinfection with harsh alcohols and phenols can turn standard PET cloudy and brittle. Our Hard Coated series features a cross-linked surface that remains "glass-clear" even after repeated exposure to industrial cleaning agents. With a surface hardness that passes the rigorous steel wool test, these sheets are perfect for high-wear applications like protective face shields, laboratory splash guards, and retail partitions. Experience the weight-saving benefits of plastic with the surface durability of glass, without the risk of shattering or surface degradation.

| Hard Coated PET Sheet | UNIT | Antistatic Silicon Free | ESD | Conductive |

| Thickness of Film Tested | mm | 0.25~1.8 | 0.25~1.8 | 0.25~1.8 |

| Width | mm | 600~ 1400 | 600~ 1400 | 600~ 1400 |

| Diameter | mm | 300~ 800 | 300~ 800 | 300~ 800 |

| Density | g/cm³ | 1.35 | 1.35 | 1.35 |

| Haze | % | 2.0(0.3mm) | 2.0(0.3mm) | 2.0(0.3mm) |

| Crystal Temperature | (℃) | 125 | 125 | 125 |

| Meliting Temperature | 248 | 248 | 248 | 248 |

| Recrystal Temperature | (℃) | 181 | 181 | 181 |

Our Advantages:

Professional Hard Coated PET Sheet manufacturer and supplier with wholesale online service and competitive pricing.

OEM & ODM services are fully supported.

Factory-direct prices for cost-effective sourcing.

Over 10 years of export experience serving global markets.

Certified with RoHS, SGS, and ISO for quality and compliance.

Holding multiple patents demonstrates robust innovation and product development capabilities.

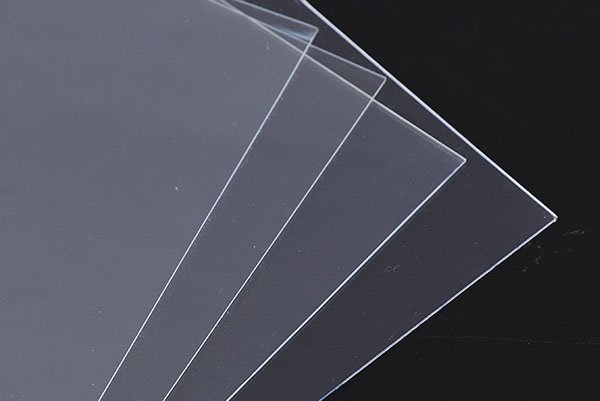

In high-performance surfacing, the gap between "standard" and "industrial grade" is defined by a single metric: surface energy. While raw PET (Polyethylene Terephthalate) offers excellent tensile strength and clarity, it remains inherently susceptible to micro-abrasion and chemical softening. Hard-Coated PET sheets solve this vulnerability through a sophisticated UV-curing process that transforms the surface at a molecular level.

The "Hard Coat" is not merely a layer of lacquer sitting on top of the plastic. It is a specialized resin—often acrylate-based—that is applied and then bombarded with high-intensity UV light. This causes cross-linking, where the molecules form a dense, three-dimensional web. The result is a dramatic increase in pencil hardness—typically moving from a soft HB to a resilient 2H or 4H rating. In practical terms, this means the surface can withstand repetitive friction from stylus pens, industrial wipes, and fingernails without developing the "haze" that typically ruins display interfaces over time.

A major "silent killer" of plastic components in medical and industrial settings is Environmental Stress Cracking (ESC). When standard PET is cleaned with aggressive solvents like Isopropyl Alcohol (IPA) or industrial degreasers, the chemicals can penetrate the polymer chains, causing them to become brittle and turn opaque. Our hard-coated sheets act as a chemical bulkhead. The cross-linked surface is non-porous and chemically inert, preventing these agents from reaching the base substrate. This ensures that the material remains optically clear even after thousands of disinfection cycles in a hospital or lab environment.

For display overlays and protective visors, transparency is a safety requirement. Standard plastics often suffer from high "haze" percentages as they age or get scuffed. Hard-coated PET maintains a light transmission rate of >89% while keeping haze levels below 1.0%. This optical precision is achieved by maintaining a consistent coating thickness (typically 3–8 microns) across the entire sheet. This consistency prevents "rainbowing" (Newton’s rings) and ensures that high-definition screens behind the PET sheet remain sharp and color-accurate.

For the manufacturer, hard-coated PET is engineered for clean processing. It offers a high-energy surface that is exceptionally compatible with screen printing inks and vacuum metallization. Unlike softer materials that might "gum up" during die-cutting, the hard-coated surface allows for crisp, burr-free edges. This reduces secondary finishing time and increases the overall yield per sheet, making it as much a financial upgrade as it is a technical one.

Superior Surface Hardness (Anti-Microscratch): Unlike standard films that dull within months, our PET coating is engineered with a specialized hard-coat layer. This significantly increases its resistance to "spider-web" micro-scratches caused by daily cleaning or surface friction, ensuring the high-gloss or deep-matte finish remains pristine in high-traffic commercial environments.

Zero-Whitening Ductility: One of the biggest headaches in fabrication is "stress whitening" at the edges. Our PET coated sheets possess high ductility, allowing the material to be bent or profile-wrapped around sharp 90-degree corners without the polymer structure breaking down. This results in a seamless, solid-color appearance that mimics expensive lacquered finishes.

High Chemical & Stain Inertia: The non-porous nature of the PET top-layer acts as a high-performance barrier. It is completely resistant to household stains (like coffee, oils, and wine) and, more importantly, withstands the harsh surfactants and alcohol-based disinfectants used in medical and laboratory settings without surface degradation or clouding.

Thermal Stability & Delamination Resistance: Using advanced cross-linking adhesive technology, the PET layer is fused to the substrate with exceptional bond strength. This prevents "edge creep" or bubbling when exposed to fluctuating temperatures, making it a reliable choice for kitchen cabinetry near ovens or in humid bathroom environments.

VOC-Free & Eco-Friendly Compliance: Our sheets are 100% PVC-free, halogen-free, and contain no volatile organic compounds (VOCs). This makes them an essential material for projects requiring LEED or WELL certification, ensuring that luxury aesthetics do not come at the cost of indoor air quality or environmental safety.

Optical Depth & Color Consistency: By utilizing high-transparency PET resins, our coated sheets provide an "internal depth" to wood grains and solid colors that standard laminates cannot match. Furthermore, our strict batch-control process ensures that the color you order today will perfectly match the color you order six months from now, which is critical for large-scale architectural projects.