Streamline your production with APET sheeting designed for high-speed thermoforming and automated de-stacking. Our sheets feature a specialized surface treatment to reduce friction, ensuring that formed trays and blisters "denest" easily without sticking—a common bottleneck in high-volume cosmetic filling. With consistent gauge control across the entire roll, you’ll experience fewer rejects and more uniform wall thickness in deep-draw cavities. Compatible with UV offset printing and hot foil stamping, this APET grade is the workhorse of the cosmetic secondary packaging industry, offering both aesthetic appeal and industrial-scale reliability.

| APET Sheet for Packaging | UNIT | Antistatic Silicon Free | ESD | Conductive |

| Thickness of Film Tested | mm | 0.25~1.8 | 0.25~1.8 | 0.25~1.8 |

| Width | mm | 600~ 1400 | 600~ 1400 | 600~ 1400 |

| Diameter | mm | 300~ 800 | 300~ 800 | 300~ 800 |

| Density | g/cm³ | 1.35 | 1.35 | 1.35 |

| Haze | % | 2.0(0.3mm) | 2.0(0.3mm) | 2.0(0.3mm) |

| Crystal Temperature | (℃) | 125 | 125 | 125 |

| Meliting Temperature | 248 | 248 | 248 | 248 |

| Recrystal Temperature | (℃) | 181 | 181 | 181 |

Our Advantages:

Professional APET Sheet for Packaging manufacturer and supplier with wholesale online service and competitive pricing.

OEM & ODM services are fully supported.

Factory-direct prices for cost-effective sourcing.

Over 10 years of export experience serving global markets.

Certified with RoHS, SGS, and ISO for quality and compliance.

Holding multiple patents demonstrates robust innovation and product development capabilities.

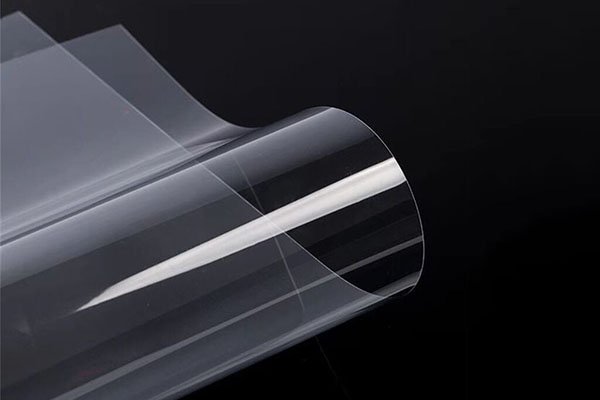

In the beauty and personal care industry, packaging is often the primary driver of perceived value. For premium skincare, perfumes, and color cosmetics, the "unboxing" experience begins with the secondary packaging. APET (Amorphous Polyethylene Terephthalate) sheet has become the material of choice for brands that refuse to choose between optical brilliance and industrial performance.

The most common failure point in cosmetic packaging is a lack of material purity. Many lower-grade PET sheets exhibit a subtle blue or gray haze that dulls the vibrant colors of makeup or the metallic sheen of perfume caps. Our cosmetic-grade APET is engineered for maximum light transmission. By utilizing virgin resin and maintaining strict gauge control during extrusion, we provide a "water-clear" substrate. This ensures that the primary product remains the hero of the shelf, encased in a protective layer that mimics the transparency of glass without the weight or fragility.

Cosmetic inserts often require "deep-draw" thermoforming to secure uniquely shaped bottles or compacts. Standard plastics often suffer from thinning or "webbing" when stretched into these complex molds. Our APET sheets are formulated with a specific thermal stability profile that allows for uniform wall thickness across intricate cavities. Furthermore, for folding box applications, our material is treated to prevent crease whitening. This ensures that even after the most aggressive 180-degree folds, the corners remain transparent and structural—retaining a crisp, high-end look that doesn't crack under pressure.

For high-volume manufacturers, the biggest headache is often on the assembly line. Static buildup can cause thermoformed trays to stick together, leading to machine downtime and manual intervention. We offer APET sheets with specialized anti-static and internal slip agents. These "denesting" properties allow for smooth de-stacking on automated filling lines, significantly increasing units-per-hour (UPH) and reducing labor costs.

Modern beauty consumers are increasingly scrutinizing plastic usage. APET is 100% recyclable and belongs to the most widely recovered plastic stream globally (RIC #1). By switching from PVC or complex laminates to APET, brands can meet their ESG (Environmental, Social, and Governance) targets without compromising the luxury "feel" of their packaging. It is a halogen-free, non-toxic solution that aligns a brand's aesthetic goals with the global shift toward a circular economy.

Feature 1: Permanent Co-extruded Antifog Layer

Benefit: Provides consistent, long-lasting fog resistance that does not wash off, ensuring a crystal-clear view of your product for the entire shelf life. This enhances product visibility and consumer appeal, directly reducing returns and increasing sales.

Feature 2: Superior Optical Clarity & High Gloss

Benefit: Creates a brilliant, high-quality presentation that makes fresh food, baked goods, and other products look more appealing and vibrant. This superior visual presentation helps your brand stand out in a competitive retail environment, driving purchase decisions.

Feature 3: Excellent Gas & Moisture Barrier Properties

Benefit: Extends the shelf life of fresh and sensitive products by protecting them from oxygen and moisture. This significantly reduces food spoilage and waste, improving your supply chain efficiency and profitability.

Benefit: Meets stringent regulatory standards for direct food contact, making it a safe and reliable choice for packaging meat, poultry, produce, and ready-to-eat meals. This ensures your brand compliance and builds consumer trust.

Feature 5: High Durability and Puncture Resistance

Benefit: Withstands the rigors of transportation, handling, and stacking without tearing. This ensures product integrity from your production line to the store shelf, minimizing damage-related losses and protecting your brand reputation.

Feature 6: Excellent Thermoformability & Machinability

Benefit: Runs efficiently on high-speed packaging and converting equipment, allowing for seamless integration into your existing production lines. This increases output, reduces downtime, and improves overall manufacturing efficiency.