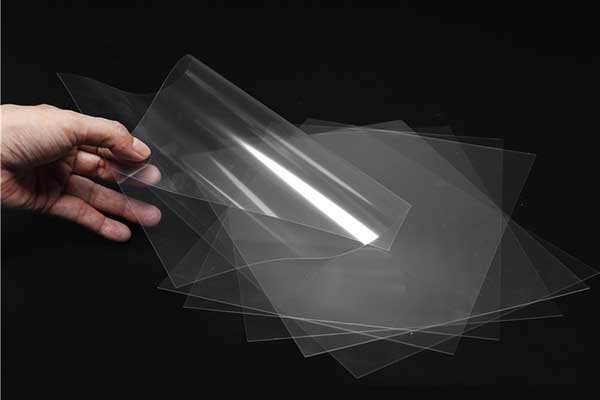

Designed for the rigors of industrial environments, our PET coated plastic sheets offer a perfect balance of flexibility and surface hardness. The PET layer is chemically bonded to the substrate to prevent delamination, even under heavy stress or thermal cycling. This coating provides an excellent surface for high-adhesion printing and protects the base material from solvents, oils, and abrasive wear. Whether you are manufacturing protective guards, control panels, or durable signage, these sheets ensure long-term performance and clarity in challenging conditions.

| PET coated plastic sheet | UNIT | Antistatic Silicon Free | ESD | Conductive |

| Thickness of Film Tested | mm | 0.25~1.8 | 0.25~1.8 | 0.25~1.8 |

| Width | mm | 600~ 1400 | 600~ 1400 | 600~ 1400 |

| Diameter | mm | 300~ 800 | 300~ 800 | 300~ 800 |

| Density | g/cm³ | 1.35 | 1.35 | 1.35 |

| Haze | % | 2.0(0.3mm) | 2.0(0.3mm) | 2.0(0.3mm) |

| Crystal Temperature | (℃) | 125 | 125 | 125 |

| Meliting Temperature | 248 | 248 | 248 | 248 |

| Recrystal Temperature | (℃) | 181 | 181 | 181 |

Our Advantages:

Professional 0.2mm 0.3mm 0.5mm 0.8mm 1mm 2mm Rigid Thin Coating PET Film manufacturer and supplier with wholesale online service and competitive pricing.

OEM & ODM services are fully supported.

Factory-direct prices for cost-effective sourcing.

Over 10 years of export experience serving global markets.

Certified with RoHS, SGS, and ISO for quality and compliance.

Holding multiple patents demonstrates robust innovation and product development capabilities.

In the demanding sectors of furniture manufacturing and industrial surfacing, the material of choice is no longer just about the base substrate—it is about the surface science that protects it. PET coated plastic sheets represent a sophisticated hybrid solution, combining the cost-effective impact resistance of a core board (such as MDF, ABS, or composite plastics) with the high-performance properties of a Polyethylene Terephthalate (PET) top layer.

The primary challenge with coated materials is delamination. Many generic films sit on top of the substrate, held only by weak surface tension. Our PET coated sheets are manufactured using a high-pressure thermal bonding process or advanced PUR (Polyurethane) adhesive systems. This creates a cross-linked bond between the PET film and the base sheet that remains stable even under extreme thermal cycling. Whether the material is used in a humid kitchen or an unheated industrial warehouse, the PET layer won't bubble, peel, or "creep" at the edges.

What truly differentiates a "premium" PET coated sheet is its resistance to abrasive wear. Traditional high-gloss or matte surfaces often suffer from "micro-scratching"—the hundreds of tiny spider-web lines that appear from simple cleaning or sliding objects across a desk. Our specialized PET coating is treated with a microscopic hard-coat layer. This significantly raises the material's Shore Hardness, allowing it to maintain its "showroom shine" or "velvet matte" finish even in high-touch environments like retail counters or medical cabinetry.

In a post-pandemic world, surfaces must withstand rigorous cleaning protocols. PET is inherently more chemically inert than many other polymers. It resists staining from common household agents like coffee and wine, but more importantly, it stands up to the harsh surfactants and alcohols found in industrial disinfectants. Because the surface is non-porous, it doesn't trap bacteria or oils, making it a "clean-surface" solution for hospitals, labs, and food preparation areas.

As industries move away from PVC-based coatings due to the release of VOCs and plasticizers, PET has become the eco-conscious standard. Our PET coated sheets are 100% recyclable and halogen-free. They provide a non-toxic alternative that doesn't sacrifice the "piano-gloss" or "deep-texture" aesthetic that designers crave. By choosing PET-coated surfaces, manufacturers are investing in a product that is safe for the end-user and compatible with modern recycling streams.

Superior Surface Hardness (Anti-Microscratch): Unlike standard films that dull within months, our PET coating is engineered with a specialized hard-coat layer. This significantly increases its resistance to "spider-web" micro-scratches caused by daily cleaning or surface friction, ensuring the high-gloss or deep-matte finish remains pristine in high-traffic commercial environments.

Zero-Whitening Ductility: One of the biggest headaches in fabrication is "stress whitening" at the edges. Our PET coated sheets possess high ductility, allowing the material to be bent or profile-wrapped around sharp 90-degree corners without the polymer structure breaking down. This results in a seamless, solid-color appearance that mimics expensive lacquered finishes.

High Chemical & Stain Inertia: The non-porous nature of the PET top-layer acts as a high-performance barrier. It is completely resistant to household stains (like coffee, oils, and wine) and, more importantly, withstands the harsh surfactants and alcohol-based disinfectants used in medical and laboratory settings without surface degradation or clouding.

Thermal Stability & Delamination Resistance: Using advanced cross-linking adhesive technology, the PET layer is fused to the substrate with exceptional bond strength. This prevents "edge creep" or bubbling when exposed to fluctuating temperatures, making it a reliable choice for kitchen cabinetry near ovens or in humid bathroom environments.

VOC-Free & Eco-Friendly Compliance: Our sheets are 100% PVC-free, halogen-free, and contain no volatile organic compounds (VOCs). This makes them an essential material for projects requiring LEED or WELL certification, ensuring that luxury aesthetics do not come at the cost of indoor air quality or environmental safety.

Optical Depth & Color Consistency: By utilizing high-transparency PET resins, our coated sheets provide an "internal depth" to wood grains and solid colors that standard laminates cannot match. Furthermore, our strict batch-control process ensures that the color you order today will perfectly match the color you order six months from now, which is critical for large-scale architectural projects.