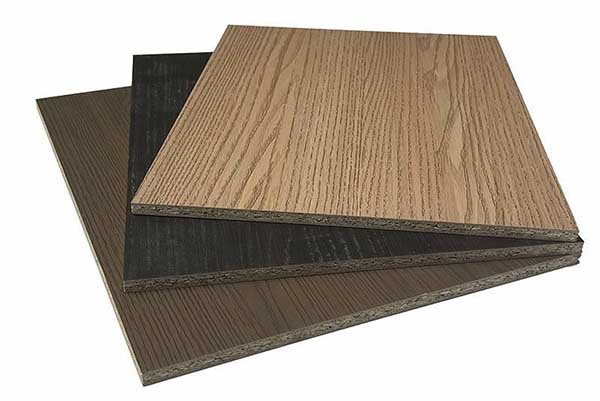

Optimize your production line with a decorative film that eliminates common fabrication headaches. Our PETG wood texture film is engineered for exceptional dimensional stability and high ductility, ensuring no "white-cracking" or grain distortion—even on deep-draw profiles and sharp 90-degree corners. Compatible with PUR hot-melt adhesives, this film provides a permanent, heat-resistant bond that outperforms traditional foils in humid environments. Upgrade to a material that meets strict environmental standards without sacrificing the tactile, premium finish your clients demand.

Our Advantages

Professional manufacturer and supplier of Wood Grain PETG Film , offering wholesale online services with competitive pricing.

Full support for OEM & ODM projects to meet customized requirements.

Factory-direct supply ensures cost-effective and stable sourcing.

Over 10 years of export experience serving global markets.

Certified with RoHS, SGS, and ISO standards to guarantee quality and compliance.

Multiple patented technologies reflect strong innovation and product development capabilities.

| Product name | PET Sheet, PETG Sheet,Polyethylene Terephthalate Sheet, PET Rollstock, Polyester Sheet, Rigid PET Film. |

| Product Category | APET, PETG, GAG, RPET, PET/EVOH/PE, PET/EVOH/PET, PET/PE, etc. |

| Shape | Roll/Sheet |

| Thickness | 0.18~1mm or Customized |

| Width | 300~1400mm |

| Quality | Virgin/Recycled |

| PET Roll Diameter | ≤38 inch |

| Die Cutting Size | A2, A3, A4 or customized according to requirements. |

| Packing | PE film inside + kraft outside+pallet (paper tube diameter: 76mm, thickness: 10mm) |

| Color | Clear, White, Blue, Brown, Pink, Green, Yellow or Customized. |

| Performance | Anti-fog, ESD (Anti-static, Conductive, Static dissipative), Corona, Printing, Coating, High impact, EVOH high barrier, Waterproof, Oil-proof, Anti-UV, etc. |

| Processing technology | Thermoforming Vacuum Blister Forming, Die Cutting. |

| Hardness | Rigid/Semi-rigid |

In the competitive landscape of interior surfacing, the shift from traditional PVC to PETG (Polyethylene Terephthalate Glycol) wood texture film represents more than just a trend; it is a fundamental upgrade in material science. As architects and furniture manufacturers move away from chlorine-based plastics, PETG has emerged as the high-performance benchmark for those who refuse to compromise between environmental ethics and aesthetic realism.

One of the most persistent issues in furniture lamination is "stress whitening." When traditional foils are bent around tight radii or 90-degree corners, the polymer structure often breaks down, leaving an unsightly white line that screams "imitation." PETG’s glycol-modified structure offers superior ductility. This allows the film to be wrapped, folded, and vacuum-pressed into complex grooves without losing its color depth or grain integrity. For the manufacturer, this means a significant reduction in factory rejects and a finished product that looks like a single, seamless piece of solid timber.

Modern consumers can distinguish between a cheap "printed" surface and a premium finish through touch alone. Our PETG films utilize Precision Synchronized Embossing. Unlike standard decorative papers that have a generic "sand" texture, our embossing rollers are digitally aligned with the wood grain print. When you see a knot in the oak or a cathedrals grain in the walnut, you feel it exactly where it appears visually. This "haptic feedback" is what bridges the gap between a synthetic film and a high-end natural veneer.

A decorative surface is only as good as its resistance to daily life. PETG is naturally more chemically inert than vinyl. It stands up to the acidity of fingerprints, the humidity of a boiling kettle in a kitchen, and the harsh surfactants found in industrial cleaning agents. Furthermore, our films are treated with a UV-inhibitor layer, ensuring that the "Fresh Pine" or "Smoked Oak" tone you install today doesn't yellow or fade when exposed to indirect sunlight through a window.

Beyond performance, PETG is the "cleaner" choice. It is 100% recyclable and free from the plasticizers and halogens found in PVC. For projects requiring LEED or WELL certification, PETG is a critical component in reducing the overall VOC (Volatile Organic Compound) footprint of a building. It provides the luxury look of rare hardwoods without contributing to deforestation or indoor air pollution.

Zero-Stress Whitening for Seamless Edges Unlike standard PVC or inferior laminates that leave a tell-tale white line when bent, our PETG film is engineered for high ductility. It can be wrapped around 90-degree corners or complex profiles without "stress whitening." This allows for a continuous, factory-seamless look on cabinet doors and furniture edges that mimics solid wood construction.

Eco-Conscious & PVC-Free Composition As global regulations tighten around plasticizers, PETG stands out as the sustainable alternative. It is 100% recyclable and free from chlorine and halogens. It does not release toxic VOCs (Volatile Organic Compounds) during installation or daily use, making it the preferred choice for LEED-certified projects and health-conscious residential interiors.

3D Synchronized Texture Realism We don’t just print wood patterns; we replicate the soul of the timber. Our films use high-definition gravure printing combined with synchronized embossing. This means the physical texture you feel—the knots, cathedrals, and fine pores—perfectly aligns with the visual grain, providing a tactile experience that is indistinguishable from real veneer to the naked eye.

Industrial-Grade Scratch & Chemical Resistance Designed for the rigors of high-traffic commercial spaces, our film features a specialized top-coat that resists micro-scratches and abrasions. It is chemically inert, meaning it won't swell or discolor when exposed to common household cleaners, oils, or even mild acids—perfect for kitchen splashbacks and hospital furniture.

Exceptional Thermal Stability PETG is naturally more heat-resistant than traditional vinyl. It maintains its dimensional stability even in sun-drenched rooms or near kitchen appliances, preventing the "shrink-back" or peeling at the seams that often occurs with lower-quality wraps. It stays flat, tight, and bonded for the life of the furniture.

Superior Processing Efficiency For manufacturers, time is money. Our PETG film is optimized for vacuum membrane pressing and flat lamination. It features a high melt strength that allows for thinner, more complex draws without tearing. Its consistent surface tension also ensures better adhesion with PUR hot-melt glues, significantly reducing factory reject rates.