We get it—switching suppliers is a risk. That’s why our Custom Skin-Sense PETG line focuses on batch-to-batch consistency and superior "workability." Engineered for seamless vacuum forming and flat lamination, our film reduces scrap rates and keeps your production line moving. You get a bespoke, ultra-matte, scratch-resistant finish that’s specifically calibrated to your machinery and your customers' high expectations.

Our Advantages

Professional manufacturer and supplier of skin sense PETG film , offering wholesale online services with competitive pricing.

Full support for OEM & ODM projects to meet customized requirements.

Factory-direct supply ensures cost-effective and stable sourcing.

Over 10 years of export experience serving global markets.

Certified with RoHS, SGS, and ISO standards to guarantee quality and compliance.

Multiple patented technologies reflect strong innovation and product development capabilities.

| Product name | PET Sheet, PETG Sheet,Polyethylene Terephthalate Sheet, PET Rollstock, Polyester Sheet, Rigid PET Film. |

| Product Category | APET, PETG, GAG, RPET, PET/EVOH/PE, PET/EVOH/PET, PET/PE, etc. |

| Shape | Roll/Sheet |

| Thickness | 0.18~1mm or Customized |

| Width | 300~1400mm |

| Quality | Virgin/Recycled |

| PET Roll Diameter | ≤38 inch |

| Die Cutting Size | A2, A3, A4 or customized according to requirements. |

| Packing | PE film inside + kraft outside+pallet (paper tube diameter: 76mm, thickness: 10mm) |

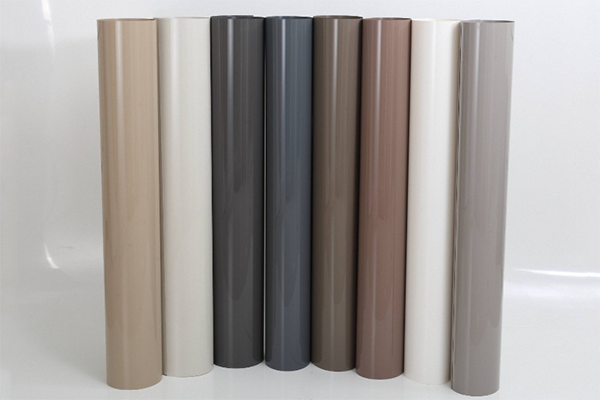

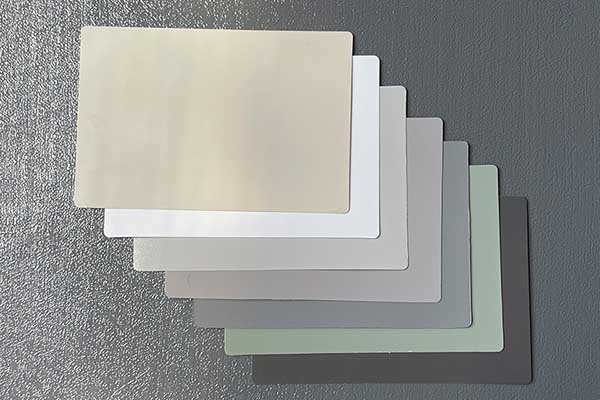

| Color | Clear, White, Blue, Brown, Pink, Green, Yellow or Customized. |

| Performance | Anti-fog, ESD (Anti-static, Conductive, Static dissipative), Corona, Printing, Coating, High impact, EVOH high barrier, Waterproof, Oil-proof, Anti-UV, etc. |

| Processing technology | Thermoforming Vacuum Blister Forming, Die Cutting. |

| Hardness | Rigid/Semi-rigid |

In an increasingly saturated furniture market, "standard" is no longer a selling point. Today’s leading furniture brands and interior architects aren't looking for a generic product; they are looking for a signature. This demand for exclusivity is exactly why our Custom Skin-Sense PETG Film service exists. We provide more than just a surface—we provide a tailored tactile identity that sets your brand apart from the competition.

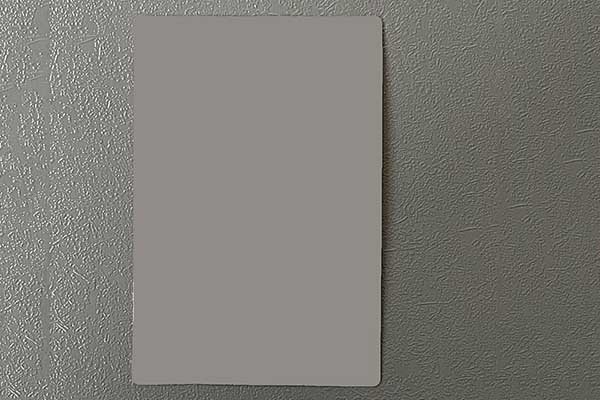

The biggest challenge in custom manufacturing is often color fidelity. Most suppliers offer a fixed palette, forcing designers to settle for "close enough." Our process for bespoke soft-touch PETG foil flips that script. We work directly with your design team to achieve high-precision color matching, from muted Morandi tones to bold, brand-specific hues. When combined with our signature "skin-sense" texture, the result is a custom color matte furniture film that offers a depth and richness of tone that standard laminates simply cannot replicate.

Customization isn't just about aesthetics; it’s about performance on the factory floor. We understand that every lamination line has its own "personality." That’s why our OEM Skin-Sense decorative wrap can be calibrated for specific thicknesses and gloss levels to ensure it behaves perfectly under your vacuum press or flat lamination machinery.

By choosing a private label PETG laminate, you aren't just getting a unique look—you’re getting a material engineered for your specific workflow. This level of customization helps reduce scrap rates and ensures that every cabinet door or wardrobe panel leaves your facility with a flawless, velvet-smooth finish that meets your internal quality benchmarks.

Beyond color and thickness, we offer the ability to fine-tune the functional properties of the film. Depending on the end-use—whether it’s high-traffic office furniture or moisture-prone bathroom vanities—we can adjust the density of the anti-fingerprint coating. This results in a tailored anti-fingerprint surface that provides the exact balance of "soft-touch" feel and rugged smudge resistance your target market requires.

Ultimately, our goal is to move beyond the traditional supplier-client relationship. By offering a fully customizable PETG solution, we allow you to focus on what you do best: designing incredible spaces. We’ll handle the science of the surface.

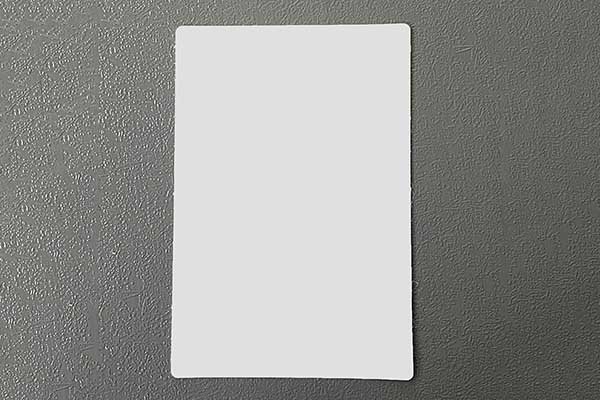

The defining characteristic of Skin-Sense film is its unique surface texture. Unlike traditional high-gloss or standard matte finishes that can feel like hard plastic, this film uses a specialized soft-touch coating. It provides a warm, velvet-like sensation under the fingertips—often described as "baby-skin" soft—which adds a layer of emotional comfort and "quiet luxury" to home furniture.

One of the biggest headaches with matte surfaces is their tendency to show every oily fingerprint and smudge. Skin-Sense PETG is engineered with a high-density, non-porous surface that repels oils. This "self-cleaning" property means that even in high-traffic areas like kitchen cabinets or wardrobe doors, the film maintains a clean, unblemished appearance without the need for constant wiping.

While it feels soft, the material is surprisingly tough. The outer layer is treated with a hardening process (often inspired by mobile phone screen protection technology). This gives it a high level of resistance against daily wear and tear, preventing the micro-scratches that usually dull the appearance of furniture over time. It offers the "painted look" of high-end lacquer but with much higher impact and scratch resistance.

PETG is a non-crystalline copolyester that is fundamentally safer than traditional PVC. It is BPA-free and often meets FDA food-contact standards. Because it is composed only of Carbon, Hydrogen, and Oxygen, it does not release toxic chlorine gas or harmful VOCs (Volatile Organic Compounds) into your home. It’s an ideal choice for health-conscious families and sustainable building projects.

Traditional finishes often fade or turn yellow when exposed to indoor lighting or indirect sunlight. Skin-Sense PETG films utilize high-quality imported masterbatches and UV-stabilizers. This ensures that the deep, elegant colors (like Morandi grays or creamy whites) remain vibrant and consistent across different production batches, maintaining the aesthetic integrity of the interior for years.

For manufacturers, the benefit lies in the material's flexibility. PETG has a lower shrinkage rate and better toughness than standard PET. It can be easily applied using flat lamination or vacuum forming without cracking at the edges. Its ability to wrap around complex curves and "memory" properties during the pressing process result in a seamless, professional finish that mimics expensive custom-painted millwork.