Tackle complex geometries with confidence. Our thick, rigid PET sheet provides superior impact resistance and allows for deeper draws without stress whitening. Ideal for forming durable food service trays, coffee pods, appliance liners, and reusable industrial components. Excellent for post-forming CNC trimming and fabrication. Submit your part design for a free formability analysis.

Our Advantages

Professional manufacturer and supplier of PET Rigid Film for Packaging, offering wholesale online services with competitive pricing.

Full support for OEM & ODM projects to meet customized requirements.

Factory-direct supply ensures cost-effective and stable sourcing.

Over 10 years of export experience serving global markets.

Certified with RoHS, SGS, and ISO standards to guarantee quality and compliance.

Multiple patented technologies reflect strong innovation and product development capabilities.

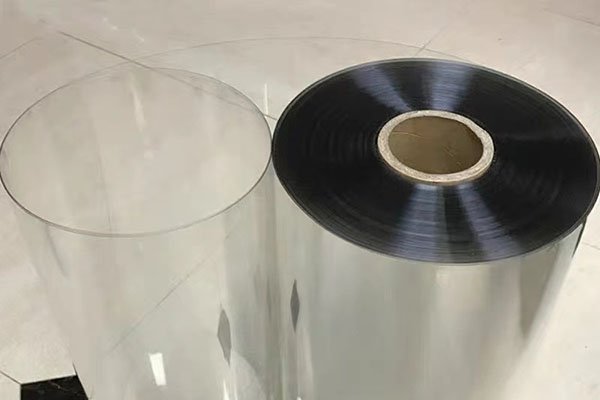

| Product name | PET Sheet, Polyethylene Terephthalate Sheet, PET Rollstock, Polyester Sheet, Rigid PET Film. |

| Product Category | APET, PETG, GAG, RPET, PET/EVOH/PE, PET/EVOH/PET, PET/PE, etc. |

| Shape | Roll/Sheet |

| Thickness | 0.18~1.8mm |

| Width | 300~1400mm |

| Quality | Virgin/Recycled |

| PET Roll Diameter | ≤38 inch |

| Die Cutting Size | A2, A3, A4 or customized according to requirements. |

| Packing | PE film inside + kraft outside+pallet (paper tube diameter: 76mm, thickness: 10mm) |

| Color | Clear, White, Blue, Brown, Pink, Green, Yellow or Customized. |

| Performance | Anti-fog, ESD (Anti-static, Conductive, Static dissipative), Corona, Printing, Coating, High impact, EVOH high barrier, Waterproof, Oil-proof, Anti-UV, etc. |

| Processing technology | Thermoforming Vacuum Blister Forming, Die Cutting. |

| Hardness | Rigid/Semi-rigid |

PET Rigid Film for Thermoforming is a high-performance material designed for use in thermoforming processes, where heat is applied to mold the film into various shapes and products. Made from polyethylene terephthalate (PET), this film offers excellent clarity, rigidity, and formability, making it a go-to choice for industries that require durable, lightweight, and visually appealing molded products.

Superior Clarity: PET rigid film provides excellent transparency, allowing for clear views of the product inside, which is especially important for packaging applications.

High Rigidity: As a rigid material, PET film maintains its structural integrity during the thermoforming process and after molding, ensuring that the final product retains its shape.

Excellent Thermoforming Properties: PET rigid film is highly formable, which means it can be easily shaped into complex designs without cracking or losing its clarity. It provides excellent detail reproduction for molded products.

Durability: The material is tough, resistant to impact, and highly durable. It is well-suited for products that need to withstand mechanical stresses and external elements.

Chemical and UV Resistance: PET rigid film offers strong resistance to various chemicals and UV exposure, ensuring that molded products maintain their quality over time, even in outdoor or harsh environments.

Eco-Friendly: PET is a recyclable material, making PET rigid film an environmentally responsible option for businesses looking to reduce waste and support sustainability.

Packaging: PET rigid film is widely used in packaging, especially for food and consumer goods. Its clarity makes it ideal for showcasing products while providing protection from damage.

Blister Packaging: It’s commonly used in the creation of blister packs for pharmaceuticals, electronics, toys, and small consumer goods.

Clamshell Packaging: Ideal for clamshell packaging, which requires a clear, rigid material to securely hold products and offer visibility for retail displays.

Medical and Cosmetic Products: PET rigid film is used in thermoforming for medical and cosmetic product packaging, offering a sterile, protective environment for sensitive items.

Consumer Goods: Other uses include thermoformed trays, clear dividers, and protective covers for various consumer products.

Cost-Effective: It is an affordable material that provides excellent value for manufacturers looking to produce high-quality thermoformed products.

Customizable: PET rigid film can be easily customized in terms of thickness, texture, and finish, giving manufacturers flexibility to create products tailored to their needs.

Sustainability: As PET is a recyclable plastic, it offers an environmentally friendly solution, aligning with modern sustainability goals.

PET Rigid Film for Thermoforming is the ideal choice for creating clear, durable, and high-quality thermoformed products, especially in industries like packaging, consumer goods, and medical applications.

Feature 1: Permanent Co-extruded Antifog Layer

Benefit: Provides consistent, long-lasting fog resistance that does not wash off, ensuring a crystal-clear view of your product for the entire shelf life. This enhances product visibility and consumer appeal, directly reducing returns and increasing sales.

Feature 2: Superior Optical Clarity & High Gloss

Benefit: Creates a brilliant, high-quality presentation that makes fresh food, baked goods, and other products look more appealing and vibrant. This superior visual presentation helps your brand stand out in a competitive retail environment, driving purchase decisions.

Feature 3: Excellent Gas & Moisture Barrier Properties

Benefit: Extends the shelf life of fresh and sensitive products by protecting them from oxygen and moisture. This significantly reduces food spoilage and waste, improving your supply chain efficiency and profitability.

Benefit: Meets stringent regulatory standards for direct food contact, making it a safe and reliable choice for packaging meat, poultry, produce, and ready-to-eat meals. This ensures your brand compliance and builds consumer trust.

Feature 5: High Durability and Puncture Resistance

Benefit: Withstands the rigors of transportation, handling, and stacking without tearing. This ensures product integrity from your production line to the store shelf, minimizing damage-related losses and protecting your brand reputation.

Feature 6: Excellent Thermoformability & Machinability

Benefit: Runs efficiently on high-speed packaging and converting equipment, allowing for seamless integration into your existing production lines. This increases output, reduces downtime, and improves overall manufacturing efficiency.